- Call Us : 0086-712-8872363

- Email Us : info@hantecable.com

XLPE Insulated PVC Sheathed YJV Power Cables, 0.6/1kV, CU/XLPE/PVC/PVC, copper conductor, XLPE insulation, PVC inner sheath, PVC out sheath, meet to GB/T 12706, IEC 60502, BS 7889.

Brand:

Hante,HANTEItem NO.:

XTD-YJV-01Order(MOQ):

100 metersPayment:

T/T 30% the deposit, the balance will be paidMarket Price:

$/M 28.88Price:

$25.18/28.88 per meterProduct Origin:

Hubei Province, China.Color:

Black or others.Shipping Port:

Wuhan, Shanghai, Guangzhou, Shenzhen, or other Chinese port.Lead Time:

Within 7-10 working days as soon as weWeight:

1680 KG/KM

XLPE Insulated PVC Sheathed YJV Power Cables

MAIN KEYWORDS

U-1000 R2V, R02V, BS 7889,

6181X, 6182X, 6183X, 6184X, 6185X, YJV power cable, CV power cable,

CU/XLPE/PVC, CU/XLPE/PVC/PVC cable.

APPLICATION CHARACTERISTICS

XLPE insulated PVC sheathed YJV power cable, copper conductor, XLPE insulation, PVC inner sheath, PVC out sheath, U0/U: 0.6/1kV. Suitable for installation in areas with reduced risk of mechanical damage; on tray, in free air or clipped direct. Suitable also for conduit and wiring installations when mechanical protection is required.

PRODUCTS STRUCTURE

---Conductor Material

Pure annealed copper wire, solid class 1, or strand class 2.

---Insulation Material

XLPE (cross-linked polyethylene).

---Insulation Color

1C: brown, blue, red, yellow, green, black, or others.

2C: brown, blue

3C: brown, blue, yellow/green

4C: brown, blue, black, yellow/green,

5C: brown, blue, black, grey, yellow/green

Remark: the insulated color is nature and close to transparent, then it with a colored tape.

---Filler Material

Fiberglass tape.

---Cabling Material

Non-woven fabrics

---Inner Sheath Material

PVC (Polyvinyl chloride).

---Armored Material

Unarmored.

---Sheath Material (out insulation)

PVC (polyvinyl chloride)

---Sheath Color

Black, or others.

---Core Number

2~5 cores, 2C~5C.

---Voltage Rate (U0/U)

0.6/1kV, 600/1000V (Um: 1.2kV).

---Working Temperature

-15℃~+90℃.

---Minimum Bending Radius

Fixed: 20 x Out Diameter.

---Production Standard

GB/T 12706, IEC 60502, BS 7889.

---Products Delivery

Within 10-15 working days as soon as we received the deposit.

REMARK

---The above information is only for

you reference, for the formal technical data, please refer to the actual cables.

---The product can have flame retardant, fire-resistant

or Low Smoking Zero Halogen properties, and their working temperature can be 90 degree, but the production process and insulation materials maybe has

a few of different.

---For the YJV power cable, according

to the practice, the common specification is 50~300 mm2.

---The OEM or OBM service

will be accepted, but the customer should be provided the authorization letter to

us in advance, and the authorization letter must be true and valid.

---Hante Cable:

Embrace New Times, Co-create Xintiandi; Focus on Quality, Foremost Service.

---Hante Cable: Good Material, Reasonable Weight, Enough Length, well-known brand wins your trust.

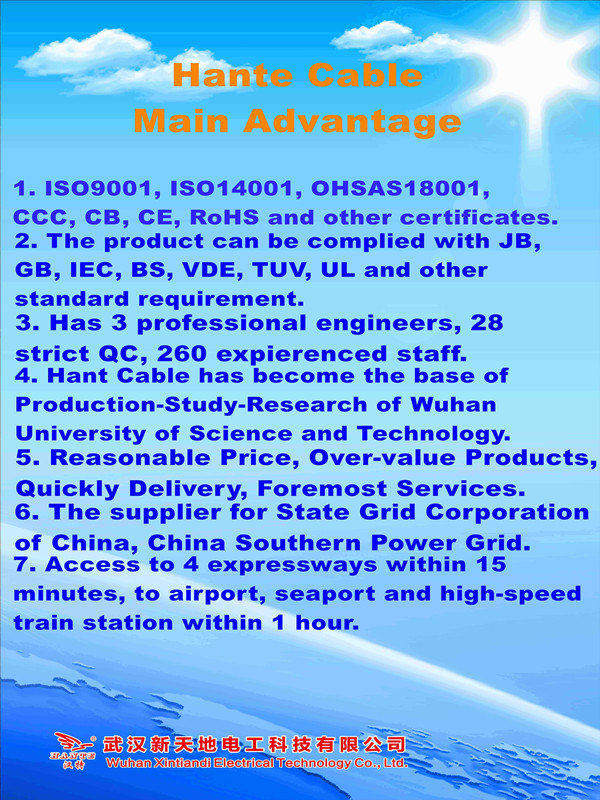

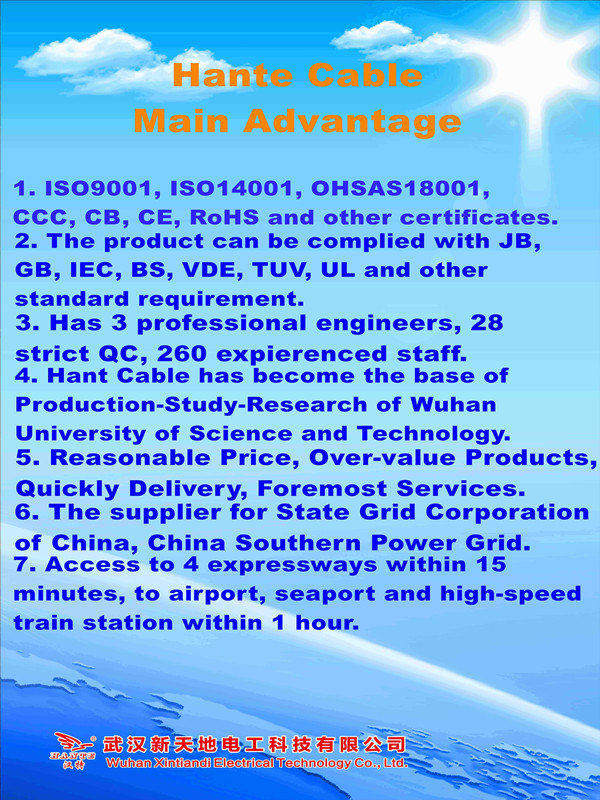

MAIN ADVANTAGE

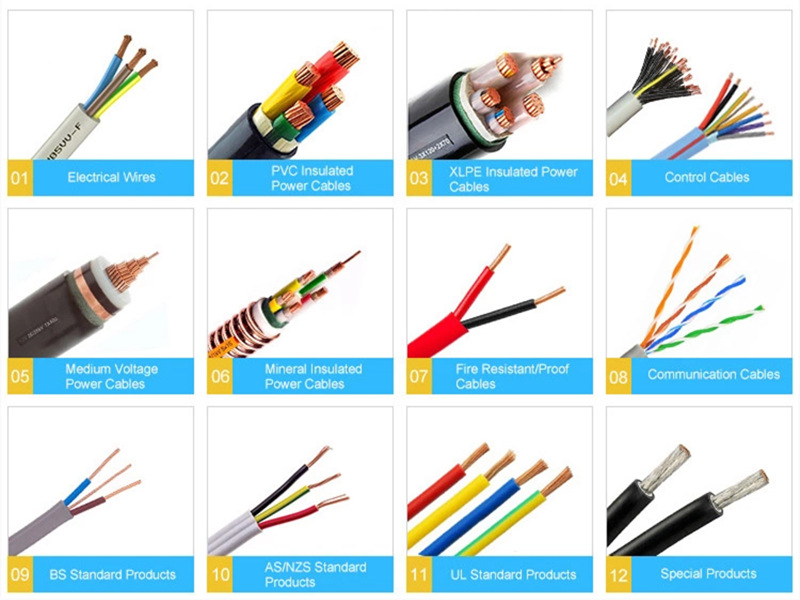

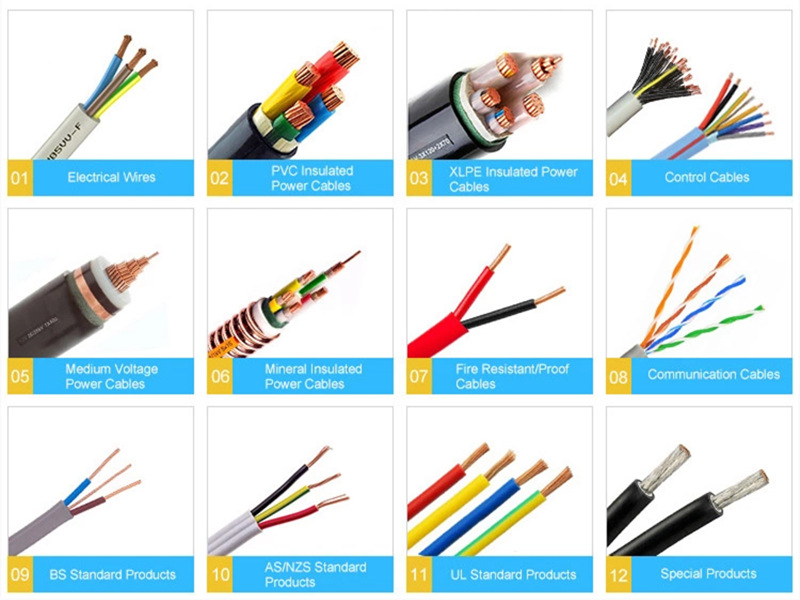

HOT-SELLING PRODUCTS

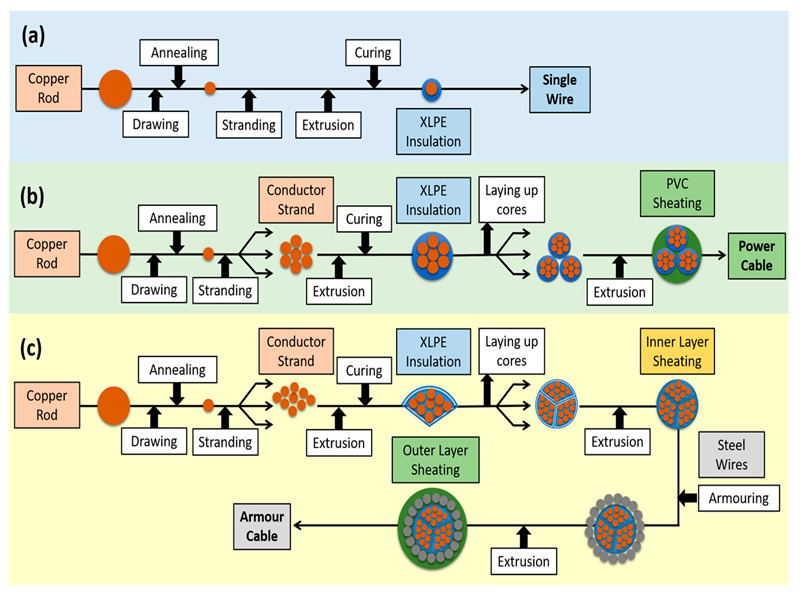

RAW MATERIAL

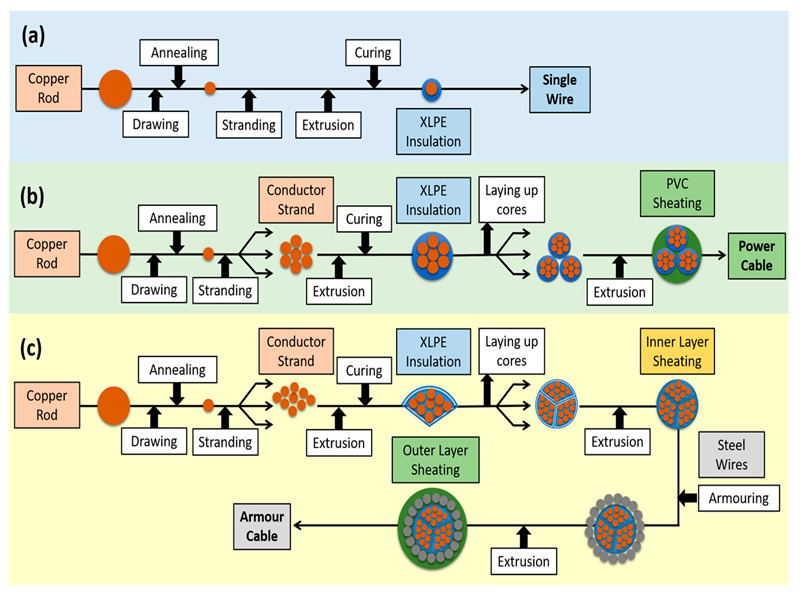

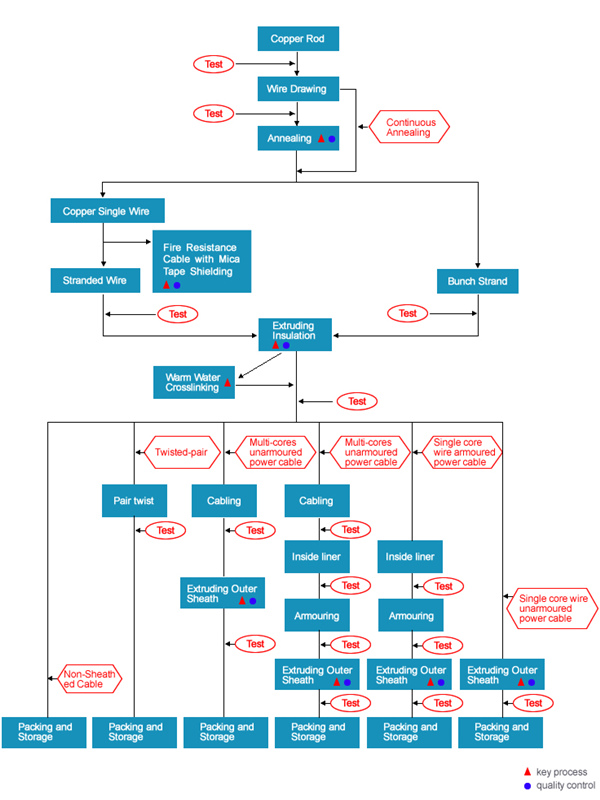

PRODUCTION PROCESS

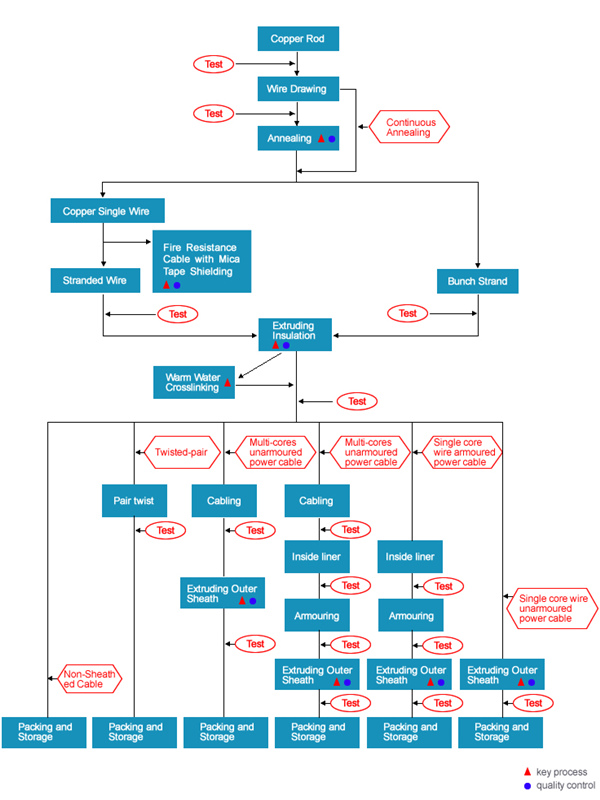

INSPECTION PROCESS

FREQUENTLY ASKED QUESTIONS

1. Are you the manufacturer or trading company?

Wuhan Xitiandi Electrical Technology Co., Ltd (Hante Cable), is the professional in wire and cables manufacturer. We can control your order from the first begining to the last. Welcome to visit Hante Cable, we'll pick you up in Wuhan airport or high-speed Railways Station.

Single Core Medium Voltage Power Cables

MAIN KEYWORDS

Single core medium voltage power cable, N2XSY power cable, BS 6622 XLPE-PVC power cable,

BS 7835 XLPE-LSZH power cable, 8.7/10kV 8.7/15kV 26/35kV and other MV power cable with voltage rate.

APPLICATION CHARACTERISTICS

Single core medium voltage power cable, copper

wire or aluminum wire conductor, semi-conductive screened tape, XLPE insulated,

semi-conductive screened tape, PVC inner sheath, copper tape screened, PVC

inner sheath, steel tape or steel wire armored (armored material is optioned), PVC

out sheath, U0/U: 3.6/6kV~26/35kV. Medium

voltage power cable is applied to the transmission and distribution lines with rated

voltage from 3.6/6kV to 26/35kV, to be laid directly in ground, outdoors,

indoors and in cable ducts.

PRODUCTS STRUCTURE

---Conductor Material

Plain

annealed compacted stranded copper wire.

---Conductor Identification

Colored tape under the screen

---Insulation Material

XLPE (cross-linked

polyethylene).

---Screen Material

Semi-conducting

layer with a copper tape screen covering each core

---Bedding Material

PVC (Polyvinyl

chloride)

---Armored Material (option)

Galvanized steel

tape, or galvanized steel wire.

---Out Sheath Material

PVC (Polyvinyl

chloride)

---Sheath Color

Black, or

others.

---Core Number

Single core,

1C.

---Voltage Rate (U0/U)

3.6/6kV~26/35kV

---Working Temperature

-15℃~+90℃.

---Minimum Bending Radius

20 x Out

Diameter

---Production Standard

---Products Delivery

Within 15-20 working days as soon as we received the deposit.

PRODUCTS SPECIFICATION

8.7/10kV, 8.7/15kV (un-armored material)

|

Cross Section Area (mm2) |

Conductor Material |

Conductor Structure (pcs/mm) |

XLPE Insulated Thickness (mm) |

PVC Sheathed Thickness (mm) |

Refer Max. Out Diameter (mm) |

Refer Net Weight (kg/km) |

Max. DC Conductor Resistance at 20℃ (Ω/km) |

Refer Current Rating in air (A) |

Refer Current Rating in ground (A) |

|

1x25 |

Copper wire |

1C 7/2.14 |

4.5 |

1.6 |

22.0 |

696 |

0.727 |

165 |

160 |

|

1x35 |

Copper wire |

1C 7/2.52 |

4.5 |

1.6 |

23.0 |

819 |

0.524 |

205 |

190 |

|

1x50 |

Copper wire |

1C 19/1.78 |

4.5 |

1.7 |

24.5 |

970 |

0.387 |

245 |

225 |

|

1x70 |

Copper wire |

1C 19/2.14 |

4.5 |

1.8 |

26.2 |

1191 |

0.268 |

305 |

275 |

|

1x95 |

Copper wire |

1C 19/2.52 |

4.5 |

1.8 |

27.9 |

1493 |

0.193 |

370 |

330 |

|

1x120 |

Copper wire |

1C 37/2.04 |

4.5 |

1.9 |

29.5 |

1760 |

0.153 |

430 |

375 |

|

1x150 |

Copper wire |

1C 37/2.25 |

4.5 |

1.9 |

31.1 |

2085 |

0.124 |

490 |

425 |

|

1x185 |

Copper wire |

1C 37/2.52 |

4.5 |

2.0 |

32.8 |

2391 |

0.0991 |

560 |

480 |

|

1x240 |

Copper wire |

1C 48/2.52 |

4.5 |

2.1 |

35.3 |

2973 |

0.0754 |

665 |

555 |

|

1x300 |

Copper wire |

1C 61/2.52 |

4.5 |

2.2 |

37.7 |

3657 |

0.0601 |

765 |

630 |

|

1x400 |

Copper wire |

1C 61/2.85 |

4.5 |

2.3 |

40.9 |

4571 |

0.0470 |

890 |

725 |

|

1x500 |

Copper wire |

1C 100/2.52 |

4.5 |

2.4 |

44.4 |

5692 |

0.0366 |

1030 |

825 |

|

1x630 |

Copper wire |

1C 126/2.52 |

4.5 |

2.5 |

48.0 |

6945 |

0.0283 |

1160 |

940 |

8.7/10kV 8.7/15kV YJV22 (Steel Tape Armored)

|

Cross Section Area (mm2) |

Conductor Material |

Conductor Structure (pcs/mm) |

XLPE Insulated Thickness (mm) |

PVC Sheathed Thickness (mm) |

Refer Max. Out Diameter (mm) |

Refer Net Weight (kg/km) |

Max. DC Conductor Resistance at 20℃ (Ω/km) |

Refer Current Rating in air (A) |

Refer Current Rating in ground (A) |

|

1x25 |

Copper wire |

1C 7/2.14 |

4.5 |

1.8 |

25.6 |

919 |

0.727 |

165 |

160 |

|

1x35 |

Copper wire |

1C 7/2.52 |

4.5 |

1.8 |

26.6 |

1055 |

0.524 |

205 |

190 |

|

1x50 |

Copper wire |

1C 19/1.78 |

4.5 |

1.8 |

27.9 |

1219 |

0.387 |

245 |

225 |

|

1x70 |

Copper wire |

1C 19/2.14 |

4.5 |

1.9 |

30.8 |

1458 |

0.268 |

305 |

275 |

|

1x95 |

Copper wire |

1C 19/2.52 |

4.5 |

2.0 |

32.7 |

1780 |

0.193 |

370 |

330 |

|

1x120 |

Copper wire |

1C 37/2.04 |

4.5 |

2.0 |

34.1 |

2312 |

0.153 |

430 |

375 |

|

1x150 |

Copper wire |

1C 37/2.25 |

4.5 |

2.1 |

35.9 |

2670 |

0.124 |

490 |

425 |

|

1x185 |

Copper wire |

1C 37/2.52 |

4.5 |

2.2 |

37.6 |

3007 |

0.0991 |

560 |

480 |

|

1x240 |

Copper wire |

1C 48/2.52 |

4.5 |

2.2 |

39.9 |

3621 |

0.0754 |

665 |

555 |

|

1x300 |

Copper wire |

1C 61/2.52 |

4.5 |

2.3 |

42.5 |

4330 |

0.0601 |

765 |

630 |

|

1x400 |

Copper wire |

1C 61/2.85 |

4.5 |

2.4 |

45.7 |

5281 |

0.0470 |

890 |

725 |

|

1x500 |

Copper wire |

1C 100/2.52 |

4.5 |

2.5 |

49.4 |

6442 |

0.0366 |

1030 |

825 |

|

1x630 |

Copper wire |

1C 126/2.52 |

4.5 |

2.7 |

53.4 |

7766 |

0.0283 |

1160 |

940 |

8.7/10kV 8.7/15kV YJV32 (Steel Wire Armored)

|

Cross Section Area (mm2) |

Conductor Material |

Conductor Structure (pcs/mm) |

XLPE Insulated Thickness (mm) |

PVC Sheathed Thickness (mm) |

Refer Max. Out Diameter (mm) |

Refer Net Weight (kg/km) |

Max. DC Conductor Resistance at 20℃ (Ω/km) |

Refer Current Rating in air (A) |

Refer Current Rating in ground (A) |

|

1x25 |

Copper wire |

1C 7/2.14 |

4.5 |

1.9 |

29.0 |

1846 |

0.727 |

165 |

160 |

|

1x35 |

Copper wire |

1C 7/2.52 |

4.5 |

1.9 |

30.0 |

2026 |

0.524 |

205 |

190 |

|

1x50 |

Copper wire |

1C 19/1.78 |

4.5 |

2.0 |

31.5 |

2237 |

0.387 |

245 |

225 |

|

1x70 |

Copper wire |

1C 19/2.14 |

4.5 |

2.0 |

33.0 |

2520 |

0.268 |

305 |

275 |

|

1x95 |

Copper wire |

1C 19/2.52 |

4.5 |

2.1 |

34.9 |

2911 |

0.193 |

370 |

330 |

|

1x120 |

Copper wire |

1C 37/2.04 |

4.5 |

2.2 |

37.5 |

3690 |

0.153 |

430 |

375 |

|

1x150 |

Copper wire |

1C 37/2.25 |

4.5 |

2.2 |

39.1 |

4005 |

0.124 |

490 |

425 |

|

1x185 |

Copper wire |

1C 37/2.52 |

4.5 |

2.3 |

40.8 |

4402 |

0.0991 |

560 |

480 |

|

1x240 |

Copper wire |

1C 48/2.52 |

4.5 |

2.3 |

43.1 |

5104 |

0.0754 |

665 |

555 |

|

1x300 |

Copper wire |

1C 61/2.52 |

4.5 |

2.4 |

45.7 |

5908 |

0.0601 |

765 |

630 |

|

1x400 |

Copper wire |

1C 61/2.85 |

4.5 |

2.5 |

48.9 |

6982 |

0.0470 |

890 |

725 |

|

1x500 |

Copper wire |

1C 100/2.52 |

4.5 |

2.6 |

52.6 |

8287 |

0.0366 |

1030 |

825 |

|

1x630 |

Copper wire |

1C 126/2.52 |

4.5 |

2.8 |

56.6 |

9789 |

0.0283 |

1160 |

940 |

26/35kV YJV (unarmored material)

|

Cross Section Area (mm2) |

Conductor Material |

Conductor Structure (pcs/mm) |

XLPE Insulated Thickness (mm) |

PVC Sheathed Thickness (mm) |

Refer Max. Out Diameter (mm) |

Refer Net Weight (kg/km) |

Max. DC Conductor Resistance at 20℃ (Ω/km) |

Refer Current Rating in air (A) |

Refer Current Rating in ground (A) |

|

1x50 |

Copper wire |

1C 19/1.78 |

10.5 |

2.2 |

38.7 |

1727 |

0.387 |

245 |

225 |

|

1x70 |

Copper wire |

1C 19/2.14 |

10.5 |

2.2 |

40.2 |

1980 |

0.268 |

305 |

275 |

|

1x95 |

Copper wire |

1C 19/2.52 |

10.5 |

2.3 |

42.1 |

2335 |

0.193 |

370 |

330 |

|

1x120 |

Copper wire |

1C 37/2.04 |

10.5 |

2.4 |

43.7 |

2650 |

0.153 |

430 |

375 |

|

1x150 |

Copper wire |

1C 37/2.25 |

10.5 |

2.4 |

45.3 |

3016 |

0.124 |

490 |

425 |

|

1x185 |

Copper wire |

1C 37/2.52 |

10.5 |

2.5 |

47.0 |

3377 |

0.0991 |

560 |

480 |

|

1x240 |

Copper wire |

1C 48/2.52 |

10.5 |

2.5 |

49.3 |

3996 |

0.0754 |

665 |

555 |

|

1x300 |

Copper wire |

1C 61/2.52 |

10.5 |

2.6 |

51.7 |

4733 |

0.0601 |

765 |

630 |

|

1x400 |

Copper wire |

1C 61/2.85 |

10.5 |

2.7 |

54.9 |

5723 |

0.0470 |

890 |

725 |

|

1x500 |

Copper wire |

1C 100/2.52 |

10.5 |

2.8 |

59.8 |

7068 |

0.0366 |

1030 |

825 |

|

1x630 |

Copper wire |

1C 126/2.52 |

10.5 |

3.0 |

63.6 |

8418 |

0.0283 |

1160 |

940 |

26/35kV YJV22 (Steel Tape Armored)

|

Cross Section Area (mm2) |

Conductor Material |

Conductor Structure (pcs/mm) |

XLPE Insulated Thickness (mm) |

PVC Sheathed Thickness (mm) |

Refer Max. Out Diameter (mm) |

Refer Net Weight (kg/km) |

Max. DC Conductor Resistance at 20℃ (Ω/km) |

Refer Current Rating in air (A) |

Refer Current Rating in ground (A) |

|

1x50 |

Copper wire |

1C 19/1.78 |

10.5 |

2.4 |

43.7 |

2600 |

0.387 |

245 |

225 |

|

1x70 |

Copper wire |

1C 19/2.14 |

10.5 |

2.4 |

45.2 |

2890 |

0.268 |

305 |

275 |

|

1x95 |

Copper wire |

1C 19/2.52 |

10.5 |

2.5 |

47.1 |

3270 |

0.193 |

370 |

330 |

|

1x120 |

Copper wire |

1C 37/2.04 |

10.5 |

2.5 |

48.7 |

3600 |

0.153 |

430 |

375 |

|

1x150 |

Copper wire |

1C 37/2.25 |

10.5 |

2.6 |

50.5 |

4020 |

0.124 |

490 |

425 |

|

1x185 |

Copper wire |

1C 37/2.52 |

10.5 |

2.6 |

52.0 |

4410 |

0.0991 |

560 |

480 |

|

1x240 |

Copper wire |

1C 48/2.52 |

10.5 |

2.7 |

54.7 |

5110 |

0.0754 |

665 |

555 |

|

1x300 |

Copper wire |

1C 61/2.52 |

10.5 |

2.8 |

57.1 |

5900 |

0.0601 |

765 |

630 |

|

1x400 |

Copper wire |

1C 61/2.85 |

10.5 |

2.9 |

60.5 |

6340 |

0.0470 |

890 |

725 |

|

1x500 |

Copper wire |

1C 100/2.52 |

10.5 |

3.0 |

65.6 |

8380 |

0.0366 |

1030 |

825 |

|

1x630 |

Copper wire |

1C 126/2.52 |

10.5 |

3.1 |

69.2 |

9790 |

0.0283 |

1160 |

940 |

26/35kV YJV32 (Steel Wire Armored)

|

Cross Section Area (mm2) |

Conductor Material |

Conductor Structure (pcs/mm) |

XLPE Insulated Thickness (mm) |

PVC Sheathed Thickness (mm) |

Refer Max. Out Diameter (mm) |

Refer Net Weight (kg/km) |

Max. DC Conductor Resistance at 20℃ (Ω/km) |

Refer Current Rating in air (A) |

Refer Current Rating in ground (A) |

|

1x50 |

Copper wire |

1C 19/1.78 |

10.5 |

2.5 |

46.9 |

4030 |

0.387 |

245 |

225 |

|

1x70 |

Copper wire |

1C 19/2.14 |

10.5 |

2.5 |

48.4 |

4380 |

0.268 |

305 |

275 |

|

1x95 |

Copper wire |

1C 19/2.52 |

10.5 |

2.6 |

50.3 |

4830 |

0.193 |

370 |

330 |

|

1x120 |

Copper wire |

1C 37/2.04 |

10.5 |

2.6 |

51.9 |

5250 |

0.153 |

430 |

375 |

|

1x150 |

Copper wire |

1C 37/2.25 |

10.5 |

2.7 |

53.7 |

5730 |

0.124 |

490 |

425 |

|

1x185 |

Copper wire |

1C 37/2.52 |

10.5 |

2.7 |

55.2 |

6160 |

0.0991 |

560 |

480 |

|

1x240 |

Copper wire |

1C 48/2.52 |

10.5 |

2.8 |

57.9 |

6940 |

0.0754 |

665 |

555 |

|

1x300 |

Copper wire |

1C 61/2.52 |

10.5 |

2.9 |

60.3 |

7810 |

0.0601 |

765 |

630 |

|

1x400 |

Copper wire |

1C 61/2.85 |

10.5 |

3.0 |

63.7 |

8990 |

0.0470 |

890 |

725 |

|

1x500 |

Copper wire |

1C 100/2.52 |

10.5 |

3.1 |

68.8 |

10500 |

0.0366 |

1030 |

825 |

|

1x630 |

Copper wire |

1C 126/2.52 |

10.5 |

3.3 |

72.6 |

12080 |

0.0283 |

1160 |

940 |

REMARK

---The above information is only for

you reference, for the formal technical data, please refer to the actual cables.

---The product can have flame retardant, fire-resistant

or Low Smoking Zero Halogen properties, but the production process and insulation materials maybe has

a few of different.

---Fore the single core medium voltage power cable, according

to the practice, the common specification is 95~300 mm2.

---The OEM or OBM service

will be accepted, but the customer should be provided the authorization letter to

us in advance, and the authorization letter must be true and valid.

---Hante Cable:

Embrace New Times, Co-create Xintiandi; Focus on Quality, Foremost Service.

---Hante Cable: Good Material, Reasonable Weight, Enough Length, well-known brand wins your trust.

MAIN ADVANTAGE

HOT-SELLING PRODUCTS

RAW MATERIAL

PRODUCTION PROCESS

INSPECTION PROCESS

FREQUENTLY ASKED QUESTIONS

1. Are you the manufacturer or trading company?

Wuhan Xitiandi Electrical Technology Co., Ltd (Hante Cable), is the professional in wire and cables manufacturer. We can control your order from the first begining to the last. Welcome to visit Hante Cable, we'll pick you up in Wuhan airport or high-speed Railways Station.